How to Select the Ideal Transformer for Your Company

Many businesses only function efficiently because of transformers. This critical equipment performs a fundamental function in many industries, transferring power and controlling voltages to ensure safe and productive workflows. If your business relies on electricity, you know how damaging a blown transformer can be to your operations. Choosing a transformer can be tricky, but with […]

Read MoreDOE Efficiency Standards for Transformers

Jump To: What Are the DOE Efficiency Standards? Benefits of Efficiency Standards to the Customer and the Industry How to Comply With Efficiency Standards Impacts of DOE Regulations and Compliant Transformers Transformers Exempt From DOE Efficiency Standards The Future of DOE Efficiency Standards More than 40% of the energy used in the United States is consumed by […]

Read MoreGuide to Transformer kVA Ratings — How to Determine What Size Transformer You Need

In many industries, including health care, manufacturing, electrical contracting, higher education and corrections, reliable, high-quality transformers are essential for keeping operations running efficiently. Large facilities and industrial processes require substantial amounts of power, and they need dependable transformers to convert the energy coming from the power plant into a form they can use for their […]

Read MoreDOE Efficiency Standards for Dry Type Transformer

More than 40% of the energy used in the United States is consumed by building operations, including the electrical equipment and appliances within those buildings. While this equipment is essential to daily functionality in homes and business locations, ensuring that these appliances use energy efficiently is also gaining importance. Since the Energy Policy and Conservation Act of […]

Read MoreGuide to Dry Type Transformers

Jump To: A transformer is a device that transfers energy from one alternating-current circuit to another. Dry type transformers are used for many applications to reduce the voltage of conventional power circuits. Learn more about what a dry type transformer does and where we use dry type transformers. What is a Dry Type Transformer? A […]

Read MoreIndicators That Dry Type Transformers Are Failing

Transformers should be built to last, and dry type transformers, in particular, avoid some maintenance issues that can occur with oil-filled transformers. However, some potential problems can still cause a transformer to fail. In this post, we’ll discuss these problems and explain how to tell if your dry type will stop working soon so you […]

Read MoreWhy Is My Dry Type Transformer Making a Loud Humming Noise?

A transformer may hum or buzz without signaling that it is malfunctioning. Many dry type transformers produce steady humming noises when magnetized and operating normally. However, if you hear a loud hum or a buzz that’s not usually present, it could signal an issue. 4 Reasons Dry Type Transformers Make Loud Humming Noises If you […]

Read MoreWhy Is Your Dry Type Transformer Overheating?

Since transformers convert high voltages into consumable power, they generate significant heat. This heat can significantly affect the transformer’s efficiency and will shorten its life span. With energy efficiency becoming a top priority in many of today’s power applications, choosing a dry type unit that can adequately meet the required power needs and subsequent thermal […]

Read More“Crime Scene Investigator” Identifies Usual Suspects of Premature Transformer Failure

Evidence reveals how to avoid transformers that wind up dying well before their time. Spoiler alert: There’s no substitute for quality. When it comes to big-ticket items, power transformers come near the top of the list. So, when they fail prematurely, it is a painful experience with damages that can far exceed the cost of a […]

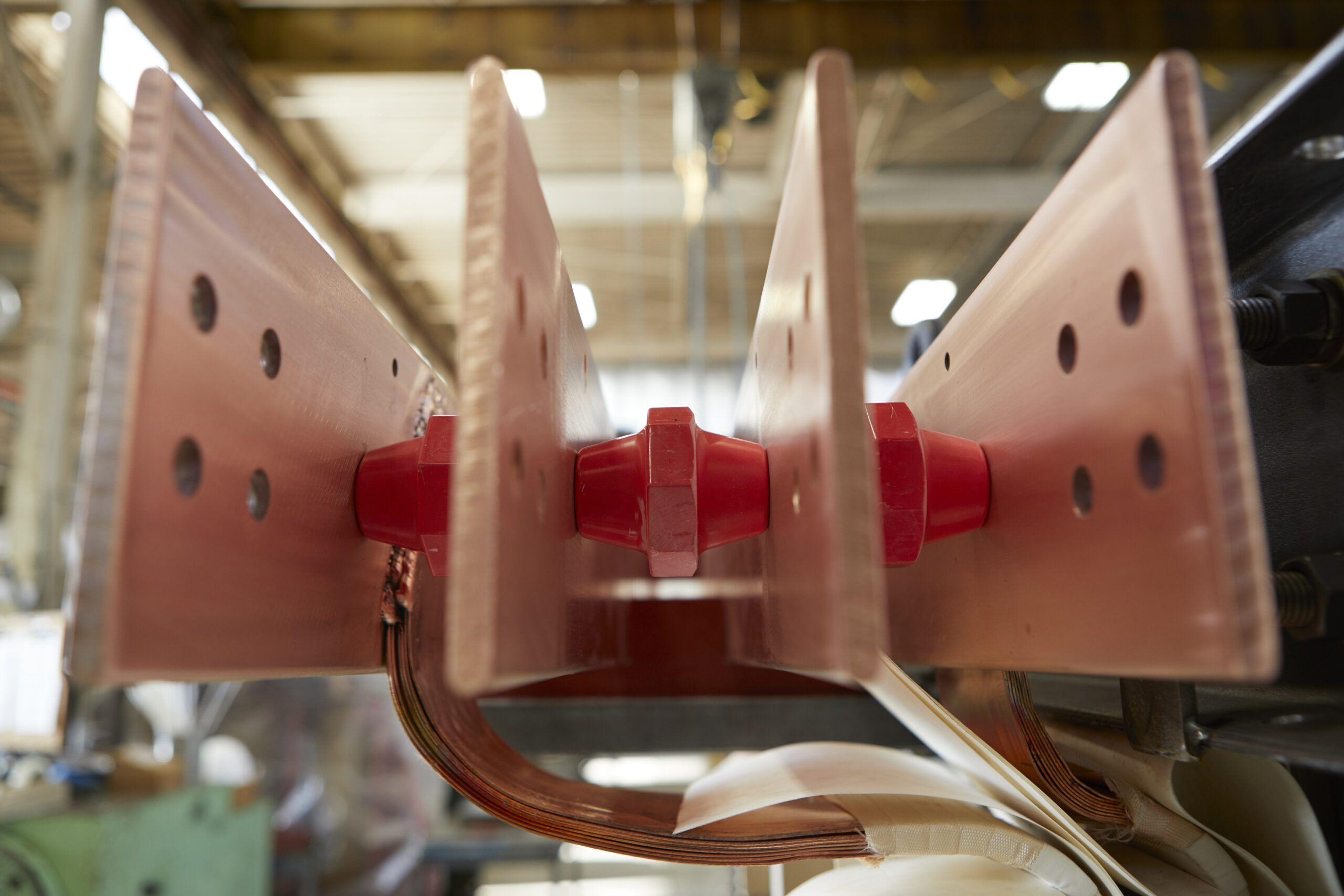

Read MoreCustom Bus Work on Transformers

When you purchase a replacement or retrofit transformer, most likely its high-voltage and low-voltage connections will not line up perfectly with your existing infrastructure due to differences in transformer models, ratings or designs. Low-voltage bus bar connections must line up perfectly with matching bolt holes and fasten together without distorting forces to ensure maximum conductance and prevent arcing. Each installation configuration is […]

Read More