Disc Wound vs. Layer Wound Transformer

One of the most common questions when selecting a medium voltage transformer is whether to choose a disc wound or a layer wound option. Understanding the difference between layer and disc winding in transformers is crucial for optimizing your medium voltage applications, as each type features unique benefits and drawbacks. Call Us Today Differences of Disc vs. Layer Wound […]

Read MoreCauses of Transformer Failure

Most of the time, your transformer may seem like an inert apparatus tucked away in a cabinet. However, when energized, it is a vibrant, living thing, transforming and feeding electrical power at 60 Hertz to your facility. In addition to the metal windings and core, it contains organic materials in the form of insulation. However, like all living things, transformers age over time […]

Read MoreCopper vs. Aluminum Dry Type Transformer Windings

Dry type transformers typically feature either copper or aluminum windings, also known as coils. Transformer windings refer to the coils within the transformer that draw and distribute power inside the unit. There are typically two windings in a dry type transformer — one that draws power from the source and another that transfers that power […]

Read MoreThe Cost of Transformer Failure in Manufacturing

Recent surveys have reported the cost of a single hour of manufacturing downtime to be anywhere between $500,000 and $5 million. The survey participants were very large, high-volume manufacturers in automated industries such as automotive, steel, chemical and pharmaceuticals. The estimates of hourly downtime costs were reported by respondents to the surveys without definitions, supporting details […]

Read MoreRound Coil vs. Rectangular Coil for Transformers

Substation transformers use round, rectangular or, less commonly, oblong core and coil assemblies. Coils facilitate the transformer’s magnetic flux flow. Coils and transformers work together to optimize performance based on design and application requirements. The transformer’s core shape determines the coil type. In other words, round iron cores must use round coils and so on. But […]

Read MoreTypes of Conductors Used in Dry Type Transformers

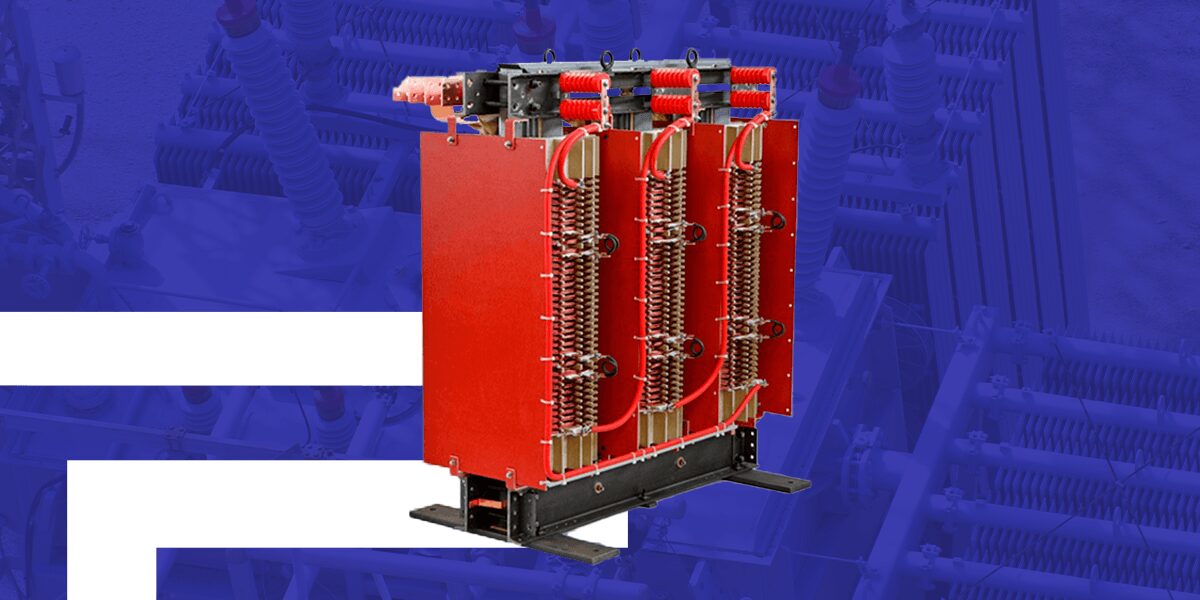

Dry type transformers usually contain windings — or coils — that act as conductors. Transformer builds typically have primary windings and secondary windings. The primary windings create input power flow, while the secondary windings convert the power and transmit it to the load through input leads. Transformers with disc windings have conductors wound on the flat […]

Read MoreDifferent Degree C-Rise Options for Dry Type Transformers

Transformers are electromagnetic devices that change the voltage levels in a circuit. Most dry type transformers contain primary and secondary windings around a magnetic steel core. Power from the incoming voltage source flows through the primary winding, while the secondary winding converts the energy and transmits it to the load. The core supports the windings […]

Read MoreDepartment of Energy Testing Procedures for Transformers

Transformers are critical pieces of equipment for supplying energy to public and private buildings, from manufacturing facilities to universities and hospitals. These systems must work correctly to transform and feed electrical energy into buildings to power daily operations. Besides working correctly and safely, transformers must also use energy efficiently. Since its founding in 1977, the U.S. […]

Read MoreTypes of Insulation Used in Dry Type Transformers

The insulation material in a transformer matters because it affects the transformer’s capacity, life span and cost. Insulation options for transformers vary by transformer type — liquid-filled or dry type. Understanding these options can help you choose a quality-made transformer with a long performance life. Insulation Used in Dry Type Transformers Transformer manufacturers have several […]

Read MoreHow to Determine What Electrical Transformer Your Company Needs

Choosing a transformer to support a facility or commercial space can seem daunting, especially if you don’t know what kind you need. One of the first steps in buying a transformer for a commercial or industrial building is determining which rating your transformer needs. A transformer’s rating comes from its voltage-ampere (VA) capacity, which must […]

Read More