- by Todd Benadum

- April 6, 2020

- Dry Type Transformers, Padmount Transformers

Jump To:

- Dry Type vs. Liquid Transformers

- Air-Cooled Transformers

- Liquid-Insulated Transformers

- Safety Requirements & Environmental Considerations

- Maintenance Considerations

- Equipment Size Requirements & Capacity

- Site Selection & Application

- Benefits and Drawbacks of Liquid Transformers

- Advantages and Disadvantages of Dry Type Transformers

A transformer allows you to use lower voltages of electricity for various applications. In most cases, you can’t power something directly through the main grid because the voltage is too high for what you’re doing. Transformers take the high voltage electricity and convert it to a lower current that commercial and industrial companies can use. Two types are dry and liquid transformers.

Although they serve the same purpose, they have different characteristics that are ideal for particular situations, environments and budgets. If you’re designing a power system for a specific project, ELSCO Transformers can help you consider various factors before investing in a solution.

Dry-Type vs. Liquid Transformers

Because transformers convert high voltage energy into more consumable power, they generate a lot of heat that the devices need to dissipate. If they aren’t cooling during the process, they can become unsafe and combust.

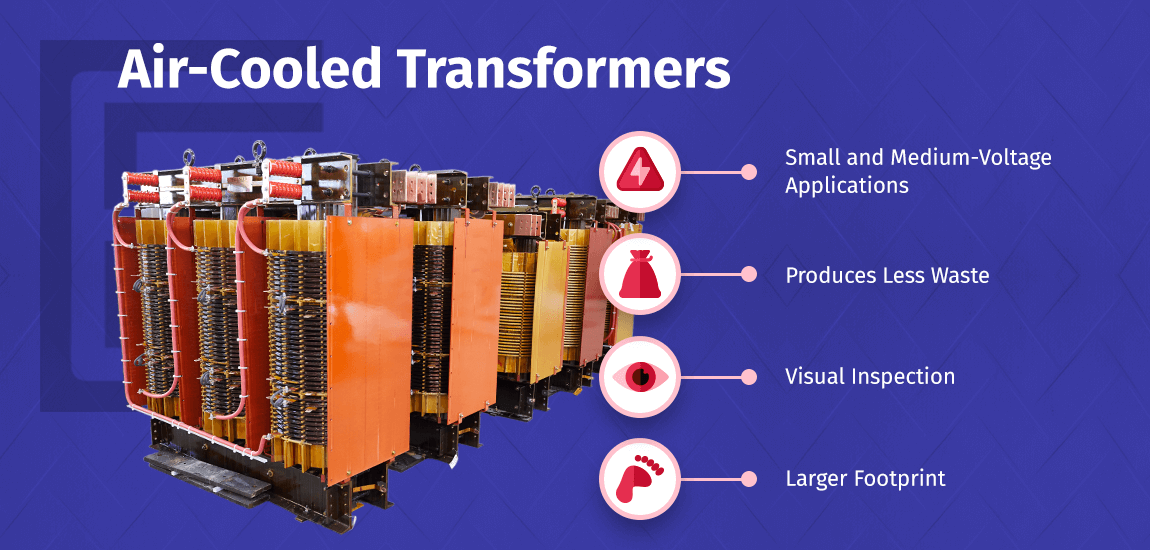

Air-Cooled Transformers

A dry transformer is a static device with a cooling medium of natural air. As the unit heats up during the conversion from higher voltage to lower voltage process, the air as well as Dupont Nomex fire resistant insulation prevents potential fires and explosions, overheating and other hazards.

Dry-type transformers are often used for small and medium-voltage applications, making them ideal for the utility, industrial and commercial industries. They also have copper or aluminum windings that are sealed in varnish. Different variations exist depending on your application and environment. Although air-cooled solutions often have a higher upfront cost compared to oil-filled units, dry types deliver the highest profit margins.

At ELSCO Transformers, we engineer dry transformers that don’t use harmful liquids like their counterpart. Our solutions provide high-efficiency performance through our advanced copper-wound design. The copper creates a cost-effective and quiet output of energy.

We work with superior materials and implement skilled workmanship to ensure our units are up to par with a multitude of demands. ELSCO Transformers uses Dupont Nomex and SG200 fiberglass insulation, as well as a round coil disc wound design.

Our primary windings have either HAPT film-covered copper wire or Dupont Nomex wrapped copper magnet wire, while our secondary windings use Nomex insulation with strip-wound copper, which eliminates vertical forces.

Our dry transformer high voltage ratings range from 2,400V to 14,400V, and our low voltage ratings range from 208V to 4,160V. We use a precise wound design for maximum cooling and short circuit protection.

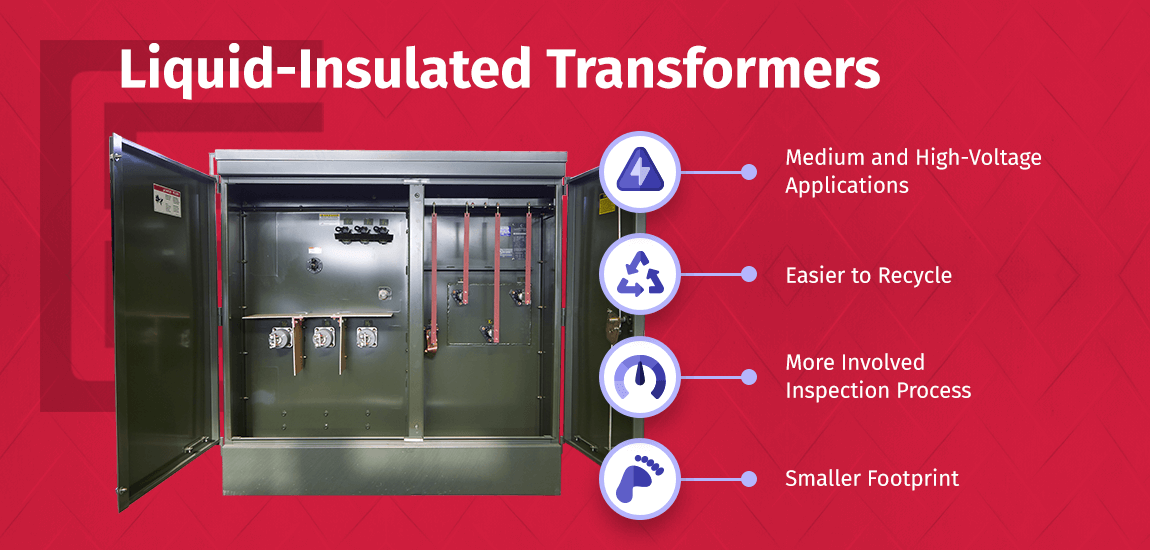

Liquid-Insulated Transformers

As a liquid transformer converts high voltages to a more usable source of energy, the unit uses a different cooling method compared to dry. Wet types often use oil or mineral oil, as well as fans, to cool. Other wet-type transformers can use silicone or hydrocarbons, which are a bit safer.

The use of fluid is a fast solution in reducing high-temperature hot spots in the unit’s coils, helping them last longer. Liquid transformers are ideal for medium voltage and high-voltage applications and can be quieter than dry types.

A liquid transformer is typically more efficient than a dry type. A wet type is smaller and needs less demand to make a conversion.

The main difference between a dry type and a liquid transformer is how they cool down. However, there are other variances worth knowing when deciding which is best for your operations.

Safety Requirements and Environmental Considerations of Dry Type vs. Liquid

A dry transformer doesn’t use toxic fluids to cool its system, so it doesn’t have to ventilate any gases. With no flammable liquids in the unit, a dry solution is less likely to catch fire or explode when experiencing overload. Air-cooled transformers are the preferred unit for indoor use because of their reliable safety measures. They are ideal for hospitals, schools and other public facilities where safety is a priority. You can also rely on dry types for outdoor applications.

When it comes to the environmental considerations of dry transformers, they are limited in recycling solutions compared to liquid components.

Liquid-filled transformers contain flammable dielectric fluid. Although the oil does well to keep the system cool, especially when it experiences an overload, it’s not good for the environment. If you have an oil-filled transformer, you will often need to contain the liquid via troughs or containment of some sort.

This type of transformer demands top safety precautions as fire and explosion prevention is crucial. Wet transformers are not ideal for indoor use, but they are quieter. If you’re installing a unit inside, consider the risk of potential fire hazards and human exposure to its dielectric fluids.

Some liquid-insulated transformers have alternative fluids available, such as silicone, natural esters and hydrocarbons, that may be nontoxic, renewable, biodegradable and have a much higher flashpoint.

Compared to a dry unit, a liquid one has many recycling and remanufacturing options available. It’s easier to obtain coil and core reclamation. For example, you can replace them when necessary, then recycle them at the end of their lifecycle. You can also recondition and reuse the transformer fluid. Check your state and local stipulations if you’re looking to salvage the copper or aluminum and steel as well.

Overall, dry transformers produce less waste and are safer, while liquid options can be easier to recycle.

Dry Type vs. Liquid Type Maintenance

The maintenance of dry type vs. liquid transformers involves two different procedures — with one being more straightforward than the other.

An air-cooled transformer requires you to conduct a visual inspection. How often you need to inspect depends on how often the unit is used. The more you rely on the transformer, the more assessments you need to make. Although a dry device is more resistant to contamination and dirt buildup, always check for accumulation. Clean the transformer’s windings, grilles and coils with compressed air, a vacuum or blower.

Dry transformer maintenance also includes the inspection for loose connections. While the upkeep of an air-cooled transformer is simple, in some cases, it can be expensive because a dry-type is limited on size and voltage rating, making it more prone to overheating during overload.

ELSCO Transformers has a five-year warranty on our new dry-type transformers to support your long-term operations. We even offer repair and rebuild services to ensure your dry transformer is running at its maximum capacity. We are here to assist you, whether you experience a breakdown or you’re conducting proactive maintenance.

A liquid transformer requires more upkeep than an air-cooled unit because of its liquid components. First, inspect and tighten the connections like you would with a dry type.

Then, check the transformer’s liquid levels and gauges while keeping an eye out for leaks. If the system has zero pressure, it could indicate a leak. Reference the local, state and federal guidelines if a major spill occurs.

Another sign of leakage can be from deteriorated parts like the gasket. Replace any worn components as necessary.

With a wet-type unit, you will also need to take liquid samples of the fluid. Conduct a dissolved gas analysis or DGA test to determine its moisture content, fire and flashpoints, contamination and dielectric strength. If the gasses are above an acceptable level, you will need to filter or replace the liquid.

A wet-type transformer requires continual maintenance compared to a dry one.

Equipment Size Requirements and Capacity

Air-cooled transformers have a larger footprint than fluid-filled versions with the same voltage and capacity. A dry unit needs larger electrical clearances because it uses air as part of the system. With its limited voltage rating and size, a dry transformer can withstand small to medium voltages, making it perfect for smaller applications. Its maximum voltage can reach up to 35kV.

A dimensional comparison of dry-type vs. liquid transformers can go either way. A wet-type transformer has a smaller footprint, but when you consider its radiators and flange ends, the space you need can be greater than that of a dry unit. If you have limited space, consider the size of each transformer option before investing. Although a liquid version may have a smaller footprint, it’s heavier.

They also have enhanced overload capacity and can handle significant loads and high voltage capacities. A liquid transformer can reach up to 1,000kV or 1,000,000 volts.

Site Selection and Application

Where you need to place a transformer is one of the most significant factors in determining which solution you may need. For example, do you have an indoor or outdoor enclosure? Other considerations include:

Are fire hazards a concern?

How much space is available?

Are there many people around the site?

A dry unit is safer for the environment because they pose less of a fire hazard. They are also ideal on sites with a lot of people. Suitable indoor applications for air-cooled transformers include hospitals, universities and residential areas. Other applications include:

Environmentally sensitive places

Fire-risk regions

Inner-city and underground substations

Oil, chemical and gas industries

Renewable generation areas

Dry-type transformers are often a better choice for businesses like offices, but can also accommodate outdoor facilities. They are more secure and less flammable.

ELSCO Transformers has an extensive catalog of dry-type transformers for applications, such as:

- Coil and core assemblies

- Digital temperature controllers and fans

- K-factor designs

- NEMA 3R enclosures with strip heaters for outdoor usage or applications

- NEMA1 or NEMA2 enclosures for indoor usage or applications

- Retrofitting with custom bus work for plug and play retrofits

- Short-circuit designs

We also specialize in designing and engineering customizable air-cooled units to fit your exact needs.

If your site is outdoors, an oil-type transformer is ideal. Oil leaks and spills, plus fire hazards, make it a riskier solution for the indoors. If you invest in a liquid unit, you can consider alternative fluids to make it more environmentally friendly. Several applications for wet transformers include:

Distributed and renewable energy sources

Governmental, commercial and industrial facilities

Larger electric utility distribution and transmission systems

Microgrids

Liquid transformers are most suitable for high voltage applications.

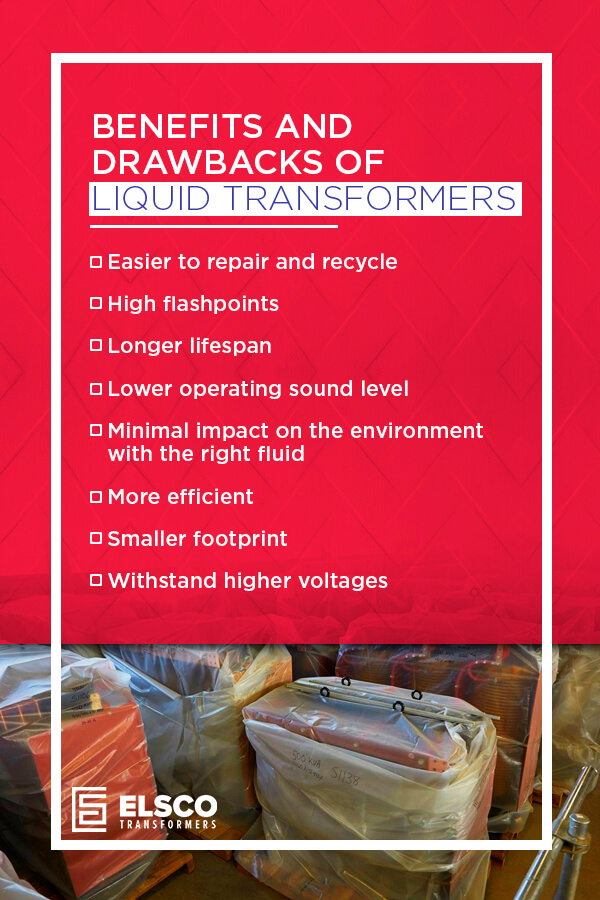

Benefits and Drawbacks of Liquid Transformers

Wet-type transformers have many positive and several negative attributes depending on your application and budget. Some advantages include:

Easier to repair and recycle

High flashpoints

Longer lifespan

Lower operating sound level

Minimal impact on the environment with the right fluid

More efficient

Smaller footprint

Withstand higher voltages

While liquid units are great in some ways, they have a few drawbacks, such as:

Greater risk of combustion and spills

More maintenance required

Oil is harsh on the environment

Advantages and Disadvantages of Dry-Type Transformers

Air-cooled transformers account for a multitude of benefits, like:

Cut environmental pollution and risks like spills and leaks

Don’t require a fire-proof enclosure

Easy inspection and removal of coils and connections

Fewer chances of fire hazards

Ideal for indoor sites for safety precautions

Less side clearance

More safety features

Practical for low and medium-voltage sites

Resistant to short circuit currents and surges

Simple installation and maintenance process

Suitable for damp areas

Some disadvantages include:

Bulkier windings

Higher upfront cost

Larger footprint

Knowing whether a dry-type or liquid-type transformer is better depends on your application, safety requirements, infrastructure and budget. It’s best to look at your needs as a whole, then figure out which solution provides the most benefits.

Dry-type transformers are ideal for small and medium-voltage uses that can accommodate both indoor and outdoor facilities. By using natural air as a cooling medium, they are less hazardous and have a lower risk of fire disruption. Air-cooled systems also need less maintenance and offer simple installation.

Choose ELSCO Transformers for Your Dry Transformer Solutions

ELSCO Transformers stocks new medium-voltage dry transformers to support a range of industries and applications. Our units are made in the United States, and we are a leading full-service company. We are known for our custom retrofits and uphold a long-standing reputation of having zero warranty issues or failures since our start in 1988. We also offer the best industry warranty of five years on new dry units. Our transformers and other solutions leave our facility within 24 or 48 hours of ordering.

Browse our dry-type transformers or contact our support team online for more information. You can also request a quote.

Are fire hazards a concern?

Are fire hazards a concern? How much space is available?

How much space is available? Are there many people around the site?

Are there many people around the site? Environmentally sensitive places

Environmentally sensitive places Inner-city and underground substations

Inner-city and underground substations Oil, chemical and gas industries

Oil, chemical and gas industries Renewable generation areas

Renewable generation areas Governmental, commercial and industrial facilities

Governmental, commercial and industrial facilities Larger electric utility distribution and transmission systems

Larger electric utility distribution and transmission systems Microgrids

Microgrids

Easier to repair and recycle

Easier to repair and recycle Longer lifespan

Longer lifespan Lower operating sound level

Lower operating sound level More efficient

More efficient Smaller footprint

Smaller footprint Withstand higher voltages

Withstand higher voltages Greater risk of combustion and spills

Greater risk of combustion and spills More maintenance required

More maintenance required Don’t require a fire-proof enclosure

Don’t require a fire-proof enclosure Easy inspection and removal of coils and connections

Easy inspection and removal of coils and connections Ideal for indoor sites for safety precautions

Ideal for indoor sites for safety precautions More safety features

More safety features Resistant to short circuit currents and surges

Resistant to short circuit currents and surges Bulkier windings

Bulkier windings Higher upfront cost

Higher upfront cost