- by Todd Benadum

- May 5, 2020

- Dry Type Transformers, Transformer Maintenance, Transformer Services

Jump To:

- Maintenance of Dry Type Transformer While Energized

- Maintenance While Dry Type Transformer is De-energized

- Checking Dry Type Transformers for Potential Problems or Defects

- Tests to Conduct for Routine Maintenance

- Preventive Maintenance Checklist for Dry Type Transformer

Keep your dry type transformer running with regular service and inspections. Use this routine dry type transformer maintenance checklist to reduce the time wasted on unnecessary repairs while improving your equipment’s operation. With regular maintenance, you will know before your transformer fails when it needs repairs or a replacement. If either situation occurs, let us at ELSCO help you with service or a new medium voltage dry type transformer.

Maintenance of Dry Type Transformer While Energized

For safety, do not perform any maintenance tasks when the transformer has energy flowing through it.

Look for adequate ventilation around the transformer. Remove anything in the area that impedes airflow. Look for dust or dirt accumulation on the surfaces of the transformer. You will need to clean these off after de-energizing the unit. However, the presence of dust indicates that the transformer is in a dusty area that will require inspections every three to six months. If you have the transformer in a dry, clean space, you may only need annual maintenance checks.

Request a Quote for Dry Type Transformers

Listen for any unusual sounds. These indicate possible mechanical problems with the unit that will need service.

Maintenance While the Dry Type Transformer Is De-energized

For testing the transformer, de-energize the transformer to begin inspection and maintenance.

First, clean any dust or dirt from the cooling fans and windings. Use either a vacuum or compressed air to avoid directly touching the components. Ideally, use both methods. Start by vacuuming off the parts followed by spraying them with compressed air that has a pressure of no more than 20 to 25 psi. Only use dry compressed air. Avoid using chemical cleaners to protect the surfaces of the transformer from damage.

Second, tighten all accessible hardware and replace any loose insulation or parts. Doing this prevents screws or nuts from working loose during regular operation.

Lastly, if you need to remove dust from your fan blades or transformer windings regularly, install filters at the bottom ventilation ports. These filters should protect the inner components from dust accumulation, which can reduce the lifespan and efficiency of the transformer. Also, just like the filters in your HVAC units, these filters must be replaced regularly so as not to clog up and restrict air flow into the enclosure in order to help circulate cooler air and exhaust the warmer air.

Checking Dry Type Transformers for Potential Problems or Defects

While cleaning the transformer, look for rust on the clamps and/or core steel, any carbonization or tracking on the windings and/or insulation. Examine the insulation and surfaces for discoloration, which could be a sign of overheating or a loose connection. If you can tighten the hardware components, do so. Otherwise, you should contact a professional to evaluate and repair the transformer.

Tests to Conduct for Routine Maintenance

During routine maintenance, you must conduct several tests of the transformer in addition to the inspection. These tests verify the operation of the unit and can find issues that do not produce visual defects.

1. Transformer Turns Ratio Test

You do not need to do a Transformer Turns Ratio (TTR) Test unless you think the system has electrical problems. For instance, if you notice signs of discoloration during your inspection, electrical issues could be at fault, and you would need to do a TTR. For accuracy of this test and safety to your personnel, do not do a TTR test yourself. Instead, contact a professional who has access to the latest testing equipment for this service. An expert will have the tools and protective gear needed to run this test correctly and safely.

2. Dielectric Absorption Test

For a dielectric absorption test, conduct it for 10 minutes from windings to windings as well as the winding to the ground. This test uses measurements at 10 minutes and one minute and divides them in a ratio, the Polarization Index (PI) ratio. To be acceptable, the PI should be greater than 2.0.

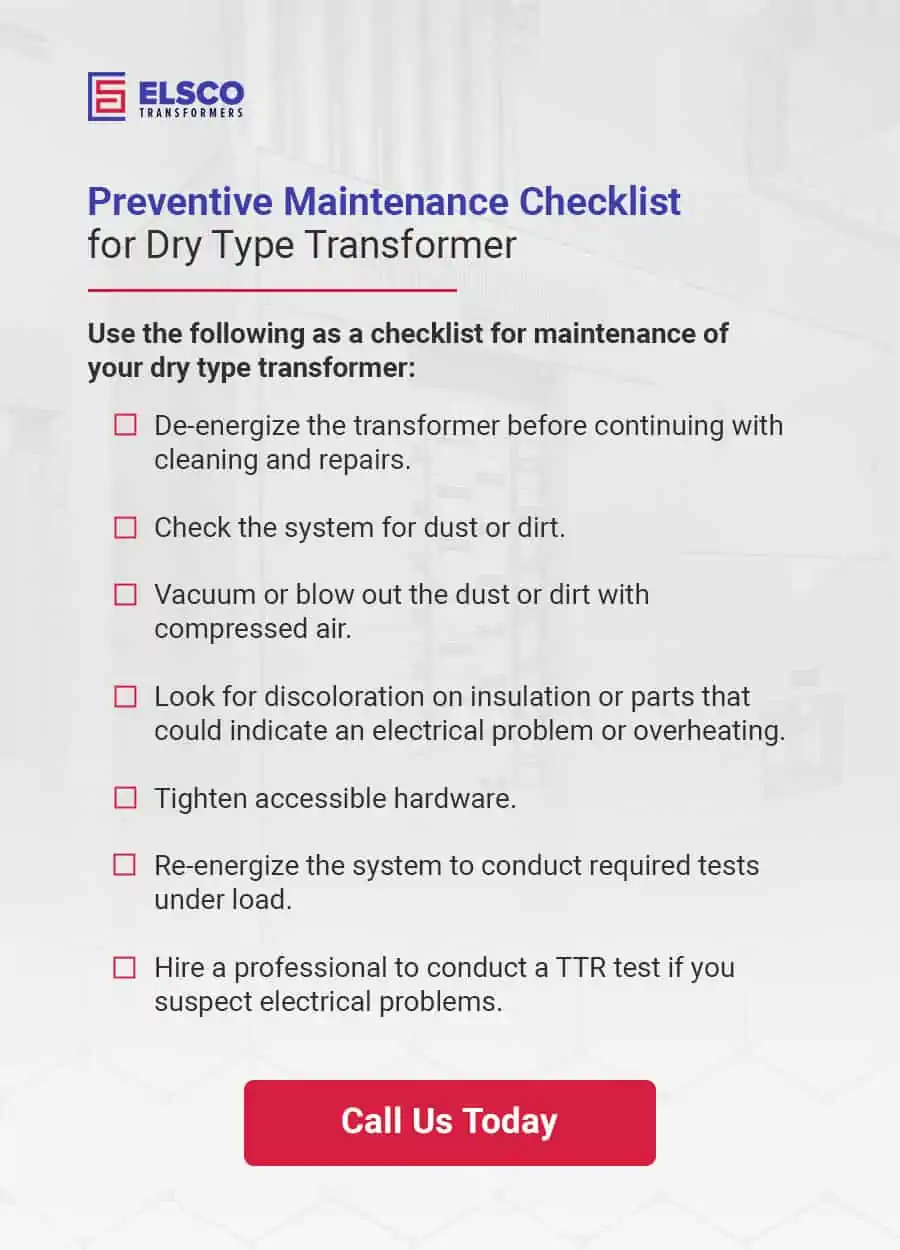

Preventive Maintenance Checklist for Dry Type Transformer

Use the following as a checklist for maintenance of your dry type transformer:

Contact us at ELSCO Transformers for repairs if you notice problems or need an emergency replacement service.

Contact Us for Service or Replacements of Your Dry Type Transformers

If your dry type transformer needs professional service, contact us at ELSCO Transformers. We offer the following services for medium voltage transformers:

- Custom builds: We can construct transformers to your specifications. If your existing dry type medium voltage transformer needs replacement, let us know what you need for a customized model.

- Emergency replacement services: In an emergency, we can replace your dry type transformer with a new model. To reduce your business downtime, we offer emergency replacement services 24 hours a day.

- General repairs: If your medium voltage transformer needs repairs beyond an annual inspection, contact us at ELSCO to get your transformer fixed quickly.

- Rebuilds: Our services include rebuilding transformers to restore their operation and efficiency.

- Retrofitting: We can retrofit many medium-voltage dry type transformers with parts needed to adapt them to a specific use. Contact us for more information about our retrofitting options.

- Rewinds: Moisture damage can devastate a transformer coil. If you only need the coil replaced, we offer rewind services to save you from having to purchase a new transformer.

For transformer repairs or replacements, contact us at ELSCO Transformers. We are the leading medium voltage transformer service company and are on call to offer you emergency and standard services and repairs for your unit.