Guide to Dry Type Transformers

Jump To: A transformer is a device that transfers energy from one alternating-current circuit to another. Dry type transformers are used for many applications to reduce the voltage of conventional power circuits. Learn more about what a dry type transformer does and where we use dry type transformers. What is a Dry Type Transformer? A […]

Read MoreIndicators That Dry Type Transformers Are Failing

Transformers should be built to last, and dry type transformers, in particular, avoid some maintenance issues that can occur with oil-filled transformers. However, some potential problems can still cause a transformer to fail. In this post, we’ll discuss these problems and explain how to tell if your dry type will stop working soon so you […]

Read MoreShould You De-Energize Transformers When Changing Taps?

Since the input power fed into a transformer may be lower or higher than the intended rate, transformers require adjustments to produce the correct secondary voltage. These fluctuations can occur for various reasons, including a power drop across a long distribution line or excessive consumption from one or more facilities. Since it is impractical and […]

Read MoreCustom Bus Work on Transformers

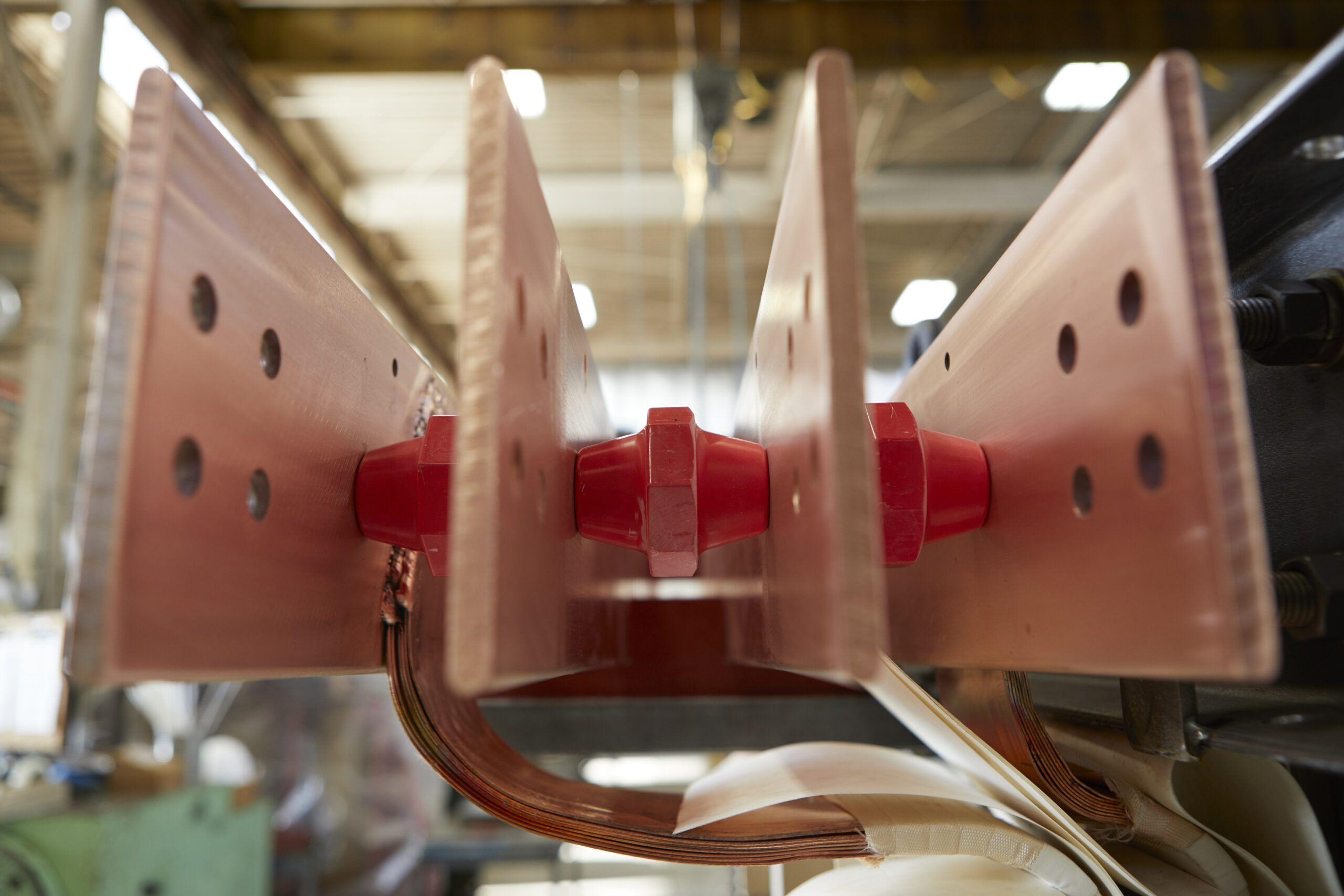

When you purchase a replacement or retrofit transformer, most likely its high-voltage and low-voltage connections will not line up perfectly with your existing infrastructure due to differences in transformer models, ratings or designs. Low-voltage bus bar connections must line up perfectly with matching bolt holes and fasten together without distorting forces to ensure maximum conductance and prevent arcing. Each installation configuration is […]

Read MoreShould Dry Type Transformers Be Installed Indoors or Outdoors?

Dry type transformers are typically one of a power system’s most critical and costly components. To achieve an optimal return on your investment, it’s critical that you select a transformer with the proper voltage and rating while following the appropriate installation protocols. Choosing a location that complies with all safety codes while not interfering with […]

Read MoreWhen Do Most Transformers Begin to Fail?

Aside from regular maintenance requirements, most operations only pay attention to their transformers once they begin failing. In a perfect world, a new transformer will provide continuous, uninterrupted service for several decades. However, lesser-quality builds often produce much shorter life spans, resulting in power interruptions and unwanted downtime. Initials Signs of Transformer Failure When a […]

Read MoreHow Long Do Dry Type Transformers Last?

Dry type transformers use circulating air to protect the internal components from overheating, unlike oil-filled units that use oil as a cooling medium. Dry type units work exceptionally well for indoor operation because they contain nothing flammable, making them a perfect choice for commercial and industrial applications requiring high fire protection. Generally, if maintenance personnel […]

Read MoreGuide to Dry Type Transformer Maintenance

Jump To: Maintenance of Dry Type Transformer While Energized Maintenance While Dry Type Transformer is De-energized Checking Dry Type Transformers for Potential Problems or Defects Tests to Conduct for Routine Maintenance Preventive Maintenance Checklist for Dry Type Transformer Keep your dry type transformer running with regular service and inspections. Use this routine dry type transformer […]

Read MoreCan You Answer These Questions About Your Transformer?

Transformers are often an afterthought. They don’t experience failures that often – but when they do, the costs can be devastating. The biggest impact for an unplanned failure is the cost for your facility to not have power. How long can your facility be without power? For some manufacturers, every hour could cost you tens […]

Read More4 Signs Your Dry Type Transformer Needs To Be Repaired—Fast

Transformers are integral to the prolonged success of any operation. That’s why it’s important to be proactive about replacing your transformer. Typically, a quality transformer should last for a decade, but often, lesser quality builds will fail well before that. Transformer failure can have steep costs in time and money. Evaluate your dry-type transformer and […]

Read More