- by Todd Benadum

- July 3, 2023

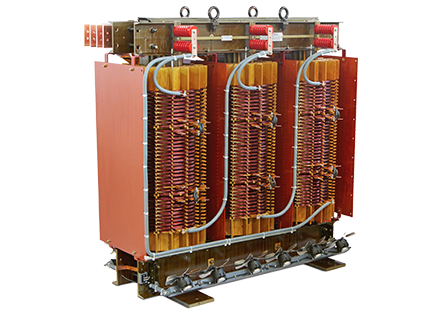

- Dry Type Transformers, Transformer Build Process

ELSCO uses DuPont Nomex® Type 410 insulation exclusively in the windings of its medium-voltage dry type transformers because it provides the strongest protection against temperatureinduced failure for the longest period of time. Nomex® 410 is a NEMA/IEC Class 220 insulating material, for which the maximum allowable exposure temperature for safe use is 220°C.

Insulation Has a Predator: Heat!

Most transformer failures are caused by a breakdown of the dielectric strength of the windings. A number of factors can contribute to this, but the most common one is a sustained increase in operating temperature above the design temperature. An anomalous temperature rise can be caused by persistent over-loading, strong harmonics that aggravate hot spots, frequent power surges, extreme ambient temperature, or failure of the air cooling system. A persistent operating temperature above a transformer’s insulation rating will lead to a failure in a very short time.

Insulation Degrades with Time and Temperature

The average operating temperature of a transformer’s coils over time is a major factor determining the transformers’ useful life. The dielectric strength of insulating materials decreases slowly with age, but the rate of decrease increases rapidly with increases in operating temperature. The relationship between dielectric aging and temperature is well known in materials engineering and can be calculated by the logarithmic Arrhenius equation (1) . A rule of thumb for electrical insulation materials is that a 10°C increase in continuous exposure temperature reduces the remaining expected life of a transformer by approximately 50% (2).

Transformer Insulation Requirements

To build a dry type transformer that is highly reliable and has a long useful life, the insulation material used for the windings must

- Provide an adequate thermal safety margin above the normal operating

temperature at full rated load, - Resist thermal degradation over an operating life of 30 years or more.

Dupont Nomex® Type 410 has been a cost-effective option for accomplishing this for over 50 years, and had been used exclusively by ELSCO in all of its dry type transformers since 1988.

Nomex® in ELSCO Dry Types

All ELSCO dry type transformers are designed for a 115°C rise in temperature (over 40°C ambient) at full rated load. The designed operating temperature at full rated load is:

40°C ambient + 115°C rise + 10°C hot spot allowance = 165°C

This is a design temperature, which in a perfect electrical world would be the normal operating temperature at full rated load; but the electrical world of transformer installations is not perfect, and departures from this temperature on the high side are not unusual. Nomex® 410 insulation provides a buffer temperature range of 55°C to accommodate any anomalous temperature increases. At actual operating temperatures less than 200°C there would be no measurable increase in the risk of imminent failure and a negligible reduction in the expected remaining life of the transformer. Even at an unlikely continuous operating temperature of 220°C, the expected life of a new ELSCO dry type transformer would be 24 years (3).

In an attempt to reduce costs, some manufacturers build to a design temperature rise of 150°C, which requires less conductor material. At that design temperature the design operating temperature would be 40°C + 150°C+ 10°C = 200°C, which will barely work with a Class 220 insulation but with a safety buffer range of only 20°C. This is cutting it pretty close, and results in a hot-running unit that may be more difficult to cool with air. It is also more difficult to meet the 2016 DOE transformer efficiency standards with a 150° design temperature rise.

With a design temperature rise of only 115°C and Nomex® insulation, ELSCO dry types run relatively cool and quiet, and have a 55°C higher range of operating temperatures in which the transformer will remain highly efficient, reliable and retain its useful life. This strong thermal endurance is an advantage in emergency replacements and many other applications.

From decades of experience in repairing and rebuilding failed transformers, ELSCO learned the vital importance of high quality insulation. Compromising on insulation quality to save money is a false economy for both manufacturer and the user. When we decided to design and build our own dry types in 1988, we researched the available insulation products and found that the Nomex® Type 410 series was the best match to our strict quality standards Itstill is. We apply it in roll form on copper secondary windings and in extruded form copper wire on the primary windings.

The superior insulation properties of Nomex®410 is one of the reasons ELSCO medium voltage dry type transformers have set a reliability standard for the US industry: We have had zero failures due to materials and workmanship since we began making them with Nomex in 1988 – a 35-year record. We are so confident of the reliability of our new dry-type transformers that we offer a five-year warranty on materials and workmanship when installed indoors in a clean and dry environment, compared to the industry norm of one year. That is confidence based on hands-on experience.

Footnotes

1 -The Arrhenius equation for10 mil Dupont Nomex® 410 is log10T = 8262/(t + 273) – 11.44, where t is the

assumed continuous operating temperature and T is the expected time for dielectric strength to be

reduced to a failure level. See Table 7 in the reference of footnote 4 below.

2 -ASTM D2304

3 -These statements are based on calculations of time-to-failure using the Arrhenius equation for Nomex® 410 in footnote 1 above. These are theoretical values based on controlled laboratory test conditions. Actual results in transformer applications may differ.

4 -Nomex® Type 410 Technical Data Sheet 04/20. Available at www.dupont.com/nomex-410-tech-data-sheet

For more information on ELSCO dry type transformers, please visit https://elscotransformers.com or call 800-232-9002 to talk with one of our transformer engineers.

Some Important Properties of Dupont Nomex® 410

- Dielectric strength of 18 – 40 kv/mm depending on thickness

- Thermal stability: Temperatures less than 200°C have little or no effect on electrical and mechanical properties

- Useful life of hundreds of years at temperatures below 200°C

- Fire resistant at 220°C : flammability threshold of 240°-350°

- Chemically stable and compatible with all varnishes and adhesives

- UL Relative Thermal Index of 220°, both electrical and mechanical

More information about Nomex® 410 can be found at https://www.dupont.com/products/nomex-400-series.html, and https://www.dupont.com/resource-center.html?BU=safety&tagId=dupont:brands/nomex_td