- by Todd Benadum

- October 30, 2025

- Dry Type Transformers, Transformer Replacements

Choosing between a new and reconditioned dry type transformer should never revolve around finding the highest-quality unit — it’s more about finding the best fit for your situation. Your timeline, budget, application and how long you’ll need the equipment all factor into this decision.

Some businesses and organizations benefit from the advanced technology and longer warranties that new transformers offer, while others need the fast availability and lower cost of reconditioned units. Knowing the advantages of each option helps you make a choice that keeps your operations running without overspending on features you don’t need.

Understanding Your Options

Manufacturers construct new dry type transformers from the ground up. They use premium-grade materials, wind the coils and assemble every component according to the production specifications. These units feature the latest design improvements, maximum efficiency ratings and comprehensive warranties that protect your investment for years down the road.

Reconditioned dry type transformers are pre-owned units professionally restored to a reliable working condition. Technicians inspect every component, replace worn parts and perform certification tests before the transformer ships. These units retain many of the original components if they are still in good shape, making them a practical choice when you need a dependable solution without the expense or long lead time of a custom build.

Benefits of New Dry Type Transformers

Some applications need the advantages that only a new dry type transformer can provide. Examples include:

- Permanent installations: If you’re setting up electrical infrastructure that needs to last for several decades, investing in a new transformer makes the most financial sense. The extended lifespan and comprehensive warranty protect you against premature failures and give you peace of mind over time.

- Critical applications: Hospitals, electrical utilities and manufacturing facilities with continuous processes require maximum reliability. New transformers with fresh components provide the dependability you need when failure is not an option.

- Custom specifications: Some installations require unique voltage ratios, grounding systems, tap configurations or physical dimensions that meet the requirements of an existing setup. New transformers can be built to your exact specifications, ensuring proper fit without workarounds or modifications to your current equipment.

- Latest technology: Newer transformer designs often incorporate advanced materials, temperature monitoring and efficiency ratings. These improvements result in lower operating temperatures, reduced energy consumption and extended equipment life.

Benefits of Reconditioned Dry Type Transformers

Reconditioned units are ideal for situations where timing, budget or temporary needs are the top priorities. These units are usually best for:

- Emergency replacements: When a transformer fails unexpectedly and your facility needs power restored immediately, reconditioned units can be shipped quickly if the correct size is in stock. This fast turnaround minimizes downtime before extended outages start incurring significant costs.

- Temporary installations: Construction sites, facility expansions and short-term projects need reliable power without investing in brand-new equipment. Pre-owned transformers provide the electrical capacity these projects require at a fraction of the cost.

- Budget constraints: Large-scale equipment purchases can sometimes involve lengthy approval processes or be prioritized behind other business needs. Refurbished transformers fit within tighter budgets while still delivering certified, tested reliability.

- Standard specifications: If your electrical requirements match typical voltage ratings and popular physical sizes, reconditioned units in stock might meet your immediate needs. Refurbished units from reputable suppliers undergo testing to ensure they meet or exceed industry standards.

Comparing the Cost and Value of New vs. Reconditioned Dry Type Transformers

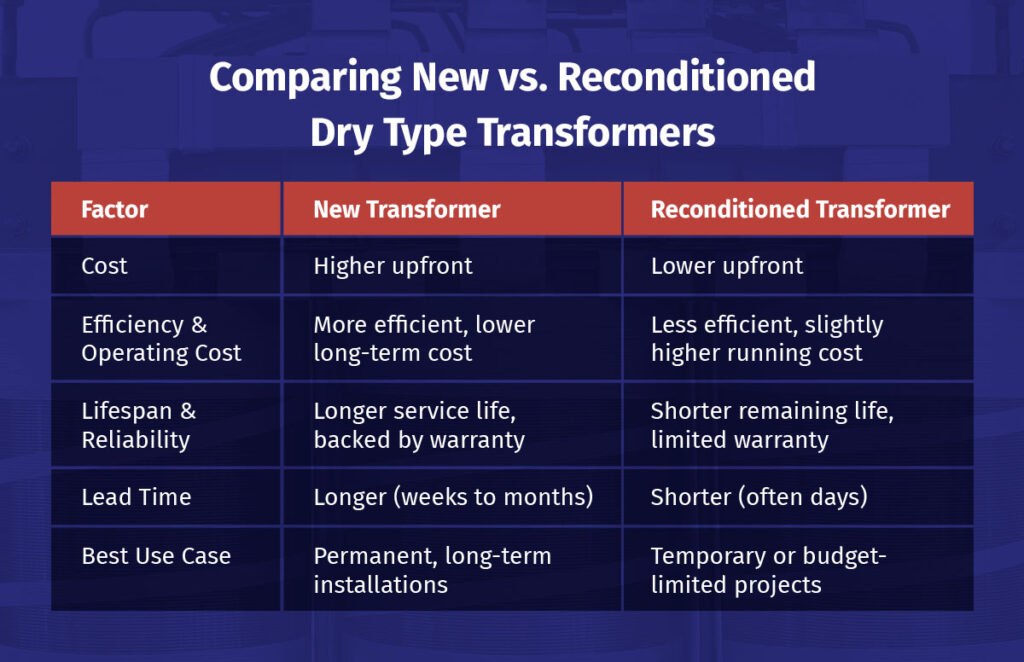

Although the price difference between a new and reconditioned dry type transformer is significant, cost alone doesn’t tell the whole story. New transformers require a larger initial investment, but they offer longer warranties and potentially lower lifetime operating costs due to improved efficiency.

Reconditioned transformers offer immediate cost savings that make sense when budgets are tight or the requirements are short-term. Lower upfront costs mean faster return on investment if you only need the equipment for a few years.

Energy efficiency also plays a role in lifetime value. Newer designs may run cooler and waste less energy, which adds up over decades of operation. While these efficiency gains might not offset the higher purchase price for a temporary installation, the savings can make new equipment more economical for a permanent system.

Lead Times and Availability

Timing often determines which option is most suitable for your situation. New dry type transformers typically require several months for custom builds since manufacturers wind the coils, assemble components and perform multistage testing. Some suppliers maintain stock of popular ratings and voltages that can be shipped within days, but these quick-ship units come in standard configurations that might not meet your operational needs.

Reconditioned transformers can ship much faster when the right unit is available. If a supplier has your required voltage rating and physical size in stock, you can often receive the transformer within days. The trade-off is that your choices are limited to what the supplier has for sale.

Quality and Reliability Considerations

Questions about reliability often arise when discussing reconditioned equipment. The answers depend entirely on the refurbishing process and the supplier’s quality standards. Reputable suppliers put reconditioned transformers through the same rigorous testing that new units receive. Technicians verify voltage ratios, check insulation resistance, test all safety systems and confirm proper operation before the unit ships.

At ELSCO Transformers, we prioritize exceptional quality and service in everything we do. Since beginning dry type transformer production in 1988, we have not experienced any failures due to materials, design or work quality. Our one-year warranty on reconditioned transformers and a three-year warranty on remanufactured or rewound units reinforce this commitment to excellence.

Making the Right Decision for Your Application

Answering several questions can help you make a more informed decision. How long will you need the equipment? Reconditioned units are usually a more cost-effective option for temporary installations lasting a few years or less, while new transformers typically offer better long-term value for permanent installations expected to last for decades.

What’s your timeline? Can you wait several months for a custom build, or do you need power restored right away? Emergencies almost always favor refurbished units when immediate availability is more important than having the latest technology or efficiency ratings.

Budget is another critical factor. If you have limited funds and need to allocate resources to multiple projects, reconditioned transformers can help stretch your budget.

Finally, think about the importance of reliability. New units go one step further in protecting your equipment, maintaining data integrity and promoting workplace safety.

How ELSCO Transformers Can Help

We feature an extensive catalog of new and reconditioned dry type units, along with padmount transformers for outdoor installations. Our team can evaluate your application and recommend whether a new or refurbished system best fits your needs. All pre-owned equipment undergoes complete testing and certification before being offered for sale or rent.

In addition to stock transformers, ELSCO offers retrofit solutions that integrate seamlessly with your existing electrical connections and infrastructure. Our custom-built transformers handle unique voltage requirements, environments or space constraints that standard systems can’t accommodate. In addition, we offer rewinding services, complete rebuilds and emergency replacements with fast response times.

Find the Right Transformer Solution

If you need additional help determining whether a new or reconditioned unit is best for your application, the experts at ELSCO can guide you. Both options provide reliable power when selected for the right situation. Contact us online today to request a quote or call 513-275-5781 for more information.