- by Todd Benadum

- March 27, 2025

- Dry Type Transformers, Transformer Build Process

Choosing a transformer to support a facility or commercial space can seem daunting, especially if you don’t know what kind you need. One of the first steps in buying a transformer for a commercial or industrial building is determining which rating your transformer needs.

A transformer’s rating comes from its voltage-ampere (VA) capacity, which must be higher than the load you plan to connect to the transformer. For commercial or industrial applications, this unit typically becomes kilovolt-amperes (kVA). You’re usually looking at a medium-voltage transformer rated between a few hundred kVA and several thousand kVA or more.

Matching the transformer’s power output and voltage to your facility’s needs can help ensure a long-lasting piece of equipment that can accommodate all your devices and load variations, like spikes in usage or specialized equipment loads. With the right equation and some basic information, we’ll help you determine what transformer rating you need.

What Transformer Rating Does Your Facility Require?

Matching electrical transformer ratings to the power needs of the connected load is essential for keeping your equipment running smoothly. If your transformer is rated for a smaller capacity than the load, you will likely overheat and destroy the transformer and possibly damage your equipment. If the transformer has a higher rating than necessary, you won’t damage it, but you’ll pay for more power than you need. By finding the sweet spot, you can support all your equipment without spending too much on electricity you won’t use. The only reason to have a higher kva rating than needed, is if you are planning on adding equipment or for growth down the road.

Before we can dive into understanding transformer voltages, you’ll need to gather some details about your application, namely your primary and secondary voltages. The primary transformer voltage, also called load voltage or input voltage, is the incoming voltage from the power company. It could be in several voltages and capable of various amperages.

The secondary transformer voltage reflects the output and needs to be compatible with the electrical load you plan to run. The number of turns in the transformer’s coils and the primary circuit’s current determine the output capabilities. Calculating the necessary value requires adding up the voltages and amperes of each piece of equipment hooked up to the transformer.

If building from scratch, you would determine the power you would need for the facility, figure out the types of hookups you could get installed from the power company, then select a transformer to balance both sides.

How to Calculate the Voltage Your Transformer Needs

To find the voltage needed for your transformer, start by gathering the electrical requirements for your equipment. These will help you identify the following values, which you can then use to calculate transformer voltages:

- Secondary voltage: First, find the required voltage of the devices you will connect to the transformer. You can typically find voltage requirements on the equipment data plates. Common voltages for consumer-grade equipment in the United States are 120 or 240 volts. Some equipment, such as a large water pump or an electric vehicle charger, runs on 480 volts. Industrial equipment can be even higher.

- Amperes: Next, find the current flow your electrical load needs. You can also get this in your equipment data plates.

For single-phase power, you multiply these two values together to find your VA requirement. For three-phase power, you also multiply by the square root of three. To convert VA to kVA, divide by 1,000.

You also want to multiply by the power factor, which represents the typical power of a load and accommodates for additional power required during startup. This factor varies based on how resistive, inductive or capacitive the load is. A purely resistive load would use a factor of 1. Most loads use a factor of less than 1. Using an incorrect factor could destroy the transformer and damage all equipment on the circuit, so it’s best to work with a professional for proper analysis.

Transformers generally come with ratings in multiples of five or 10, so round up to a slightly higher rating than the one you calculated. For example, if you calculated 12.25 kVA, a 15-kVA transformer might be a good choice.

You can then use your secondary voltage and amperes to identify the maximum current the transformer can support. Divide the VA by the secondary voltage to calculate amperes.

Keep in mind that the above guidelines are for standard, steady loads. If you’ll be starting your transformer often or you work with specialized loads like medical equipment or motors, your demands might be more complex. In these cases, you’ll likely want to consult a professional to determine what transformer rating you need.

Another factor to consider when sizing your electrical transformer is the potential for expansion. If you plan to increase the load on the transformer or expand your facility in the future, consider getting a transformer with a higher rating. If you do not plan to expand, a lower rating can help you maintain better efficiency.

ELSCO Transformers Will Help You Find the Right Transformer

Calculating dry type transformer voltages can be tricky, but it’s just one part of the equation. At ELSCO Transformers, we help you with every aspect of choosing a transformer. Our knowledgeable team members have decades of combined experience in the industry and have been helping customers with their transformer demands for over 30 years. We work with a wide range of transformers and applications and serve clients across industries.

From manufacturing facilities to colleges to medical centers, clients of all types turn to the ELSCO Transformers team for reliable, long-lasting transformers that fit their unique needs. We’ll take the time to learn about your application and set you up with the right system. Our plug-and-play retrofit options even allow you to get up and running within just four hours of the transformer’s delivery to your site. We can customize your transformer, too, such as adding low voltage custom bus work or designing a completely custom unit.

Our unmatched customer support doesn’t end with your purchase. We can also help with repairs, emergency replacements and installation guidance, a crucial yet often overlooked aspect of acquiring a transformer that can affect your downtime in the future. Improper installation can cause unexpected delays or breakdowns, leading to high costs and negative business effects. We offer support and customization to help you get this aspect of buying a transformer right, and we have engineers available 24/7 to answer questions and solve any problems related to your purchase.

At ELSCO Transformers, we focus on the long game. We aim to set you up with a long-lasting, dependable transformer that offers a high return on investment, and our expert team is up for the job.

Contact ELSCO Transformers for Dry Type Transformers!

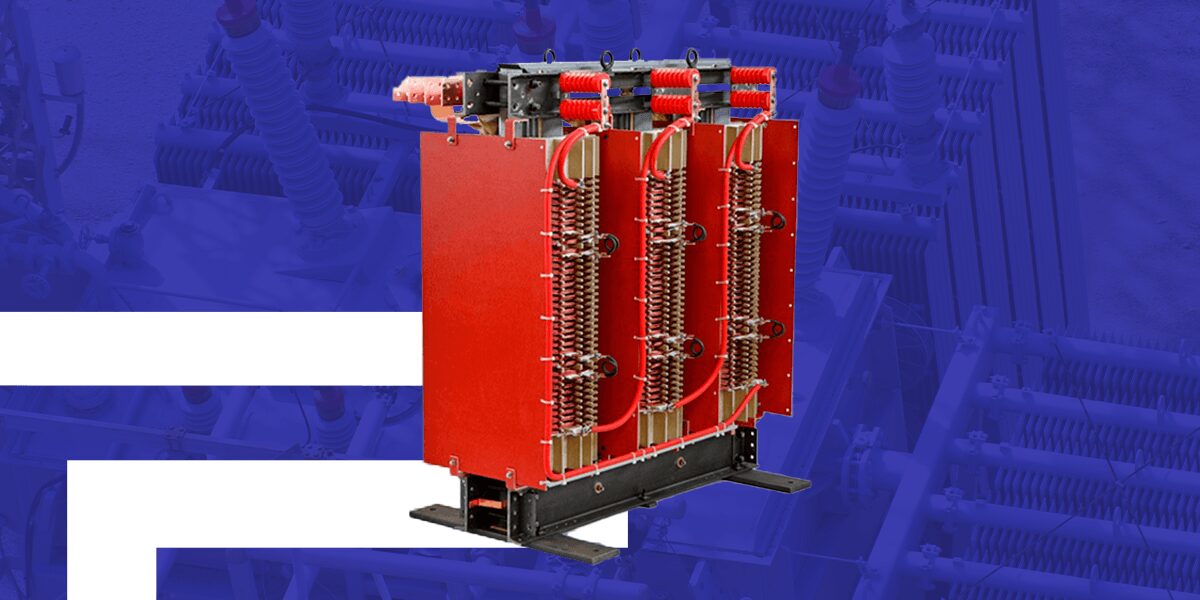

Our medium-voltage dry type transformers use copper conductors and offer exceptional reliability. We offer ready-to-ship products rated from 500 kVA to 2,500 kVA with primary transformer voltage ratings that range from 2,400 volts to 13,800 volts. When used indoors, new dry type transformers have an industry-best five-year warranty, while remanufactured ones have a three-year warranty — but we haven’t seen any failures in our installed units since we started making them in 1988.

If you need your transformer right away, we typically have 95% availability on our off-the-shelf units. Depending on the required modifications, we can often ship them out within 24-48 hours after you place your order. Reach out to us today to request a quote or get help finding the right voltage for your transformer.