- by Todd Benadum

- October 28, 2025

- Dry Type Transformers

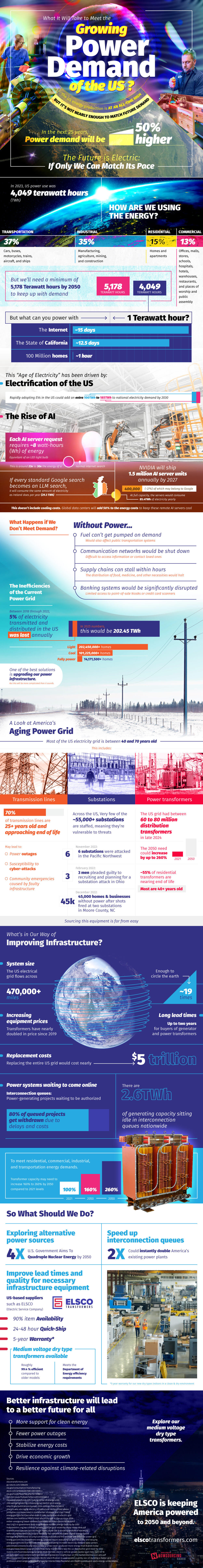

America’s power demand is surging, but our aging grid can’t keep up. To meet the future, we need smarter, more resilient infrastructure—starting with transformers built here in the United States.

Embed this graphic on your site:

<a href="https://elscotransformers.com/blog/elsco-meeting-growing-power-demand/"><IMG SRC="https://elscotransformers.com/wp-content/uploads/2025/11/elsco-meeting-growing-power-demand.jpg" alt="US’s Growing Power Demand" width="800" border="0" /></a><br />Source: <a href="https://elscotransformers.com/">ELSCO Transformers</a>Growing Power in the U.S. — Protect Your Facility From Grid Instability

The United States is entering an era of unprecedented energy consumption. With the rapid expansion of artificial intelligence (AI) data centers and the widespread electrification of the transportation sector, national power demand is surging.

For facility engineers, plant managers and procurement officers, these national statistics signal potential challenges ahead, from local grid constraints to the availability of essential equipment. As national demand outpaces generation capacity, the importance of securing reliable power and sourcing dependable infrastructure equipment grows.

Understanding how these shifts impact your facility is the first step toward insulating your operations from the rising volatility of the U.S. power grid.

How Rising Power Demand Creates Material Scarcity

The drivers of growing power demand in the U.S. are the digitization of the economy and the electrification of logistics. While these advancements promise efficiency, they are rapidly absorbing available grid capacity.

Data centers, specifically those powering generative AI, are distinct from traditional industrial loads. They require significant, continuous power density. According to the Department of Energy (DOE), data centers accounted for 4.4% of the total U.S. electricity use in 2023. The DOE projects this figure to increase to 6.7-12% of total demand by 2028 as AI adoption accelerates. The rising adoption of electric vehicles (EVs) is also adding substantial load to the grid, often in concentrated geographic hubs.

This “double-edged sword” creates a secondary challenge for industrial facilities: material scarcity. The significant growth of data centers and EV charging infrastructure consumes vast amounts of grain-oriented electrical steel (GOES) and copper — the raw materials required to build industrial transformers. As hyperscale tech companies buy up available inventory, manufacturing facilities are finding themselves at the back of the line for essential power distribution equipment.

The Vulnerability of Aging Infrastructure

As demand rises, the physical infrastructure that distributes that power is under considerable strain. The DOE reveals that the nation’s electrical power grid cannot currently meet the expected demand while maintaining affordable energy.

With this widening infrastructure gap, the National Renewable Energy Laboratory (NREL) states that transformer capacity requirements could increase by up to 260% by 2050 to keep pace with electrification goals. As the utility sector races to upgrade this capacity, existing industrial equipment is often left vulnerable to the resulting grid instability.

For a plant manager, operating with aging transformers in today’s environment is a gamble. Modern industrial loads are often nonlinear, creating harmonics and power quality distortions that generate excess heat in transformer coils. This excess heat accelerates the degradation of the transformer’s insulation, which is the primary determinant of its operational lifespan.

Once the insulation becomes brittle, the risk of unplanned failure increases considerably. Aging legacy units are less equipped to handle these stresses, and when combined with the voltage fluctuations common in an overburdened grid, the risk of failure increases significantly.

Navigating Modern Supply Chain Barriers

As manufacturing capacity is increasingly allocated to large-scale grid upgrades and data center expansion, industrial buyers can face significant delays. This procurement bottleneck means that facilities may need to operate with a spare unit to promote continuity. The “interconnection queue” for new power projects further complicates the landscape, making it unlikely that grid relief will arrive soon. To protect continuous operations, many facility managers are shifting from reactive maintenance to proactive strategic stocking.

This shift is more than just an inventory adjustment — it is a fundamental change in risk management. It requires facility leaders to move from a cost-centric, “just-in-time” mindset to a resilience-focused, “just-in-case” strategy, where a spare transformer is viewed as a critical insurance policy against lost production.

Securing Domestic Reliability With ELSCO Transformers

When the national supply chain is gridlocked, the solution lies in domestic agility. ELSCO Transformers maintains a vast catalog of American-made medium voltage transformers, setting us apart from the industry-wide backlog.

While other manufacturers quote lead times in years, ELSCO Transformers provides quick shipping. Our in-stock dry type and padmount systems leave our facility within 24 to 48 hours, depending on what modifications need to be made. This speed is critical for minimizing downtime during emergency outages.

We deliver this domestic reliability through a focus on superior engineering and industry-leading support:

- Superior build quality: We engineer our transformers for resilience using copper windings for their conductivity and tensile strength. This build quality enables the system to withstand the thermal and mechanical stresses of modern industrial loads far more effectively than mass-produced alternatives.

- Long-term value: The superior resilience of our copper-wound designs translates directly to a longer operational life and a lower total cost of ownership, promoting reliability even in the most demanding electrical environments.

- Industry-leading warranties: We back our commitment to quality with an industry-leading five-year warranty on new dry type models and a three-year warranty on remanufactured systems, giving you long-term peace of mind.

- U.S.-based manufacturing: With our domestic manufacturing and inventory, facility managers gain a reliable partner that can bypass global logistics delays to keep critical operations running.

Secure Your Uptime Against Growing Power Demand in the U.S.

The U.S. power demand is on a steep trajectory, but you don’t have to let these national trends impact your facility’s uptime. By understanding the risks associated with aging infrastructure and the reality of extended lead times, you can take proactive steps to secure your power supply now. Whether you are facing an emergency replacement or are planning a proactive upgrade, ELSCO Transformers provides the speed and quality required for today’s industrial landscape.

Call 800-232-9002 to discuss your voltage requirements or request a quote to get started.

Sources:

- https://www.energy.gov/articles/department-energy-releases-report-evaluating-us-grid-reliability-and-security

- https://www.weforum.org/stories/2025/01/grid-flexibility-for-resilient-equitable-digital-energy-future/

- https://emp.lbl.gov/publications/queued-2024-edition-characteristics

- https://www.msci.org/u-s-government-aims-to-quadruple-nuclear-energy-capacity-by-2050/

- https://www.nrel.gov/news/detail/program/2024/how-many-transformers-will-the-us-distribution-grid-need-by-2050

- https://emp.lbl.gov/publications/queued-2024-edition-characteristics

- https://interestingengineering.com/energy/us-electric-grid-energy

- https://am.jpmorgan.com/content/dam/jpm-am-aem/global/en/insights/eye-on-the-market/electravision-amv.pdf

- https://www.utilitydive.com/news/electric-transformer-shortage-nrel-niac/738947/

- https://www.heritage.org/homeland-security/commentary/substations-the-weakest-link-americas-power-grid

- https://www.energy.gov/gdo/articles/what-does-it-take-modernize-us-electric-grid

- https://interpro.wisc.edu/aging-electric-infrastructure-in-the-united-states/

- https://www.eia.gov/tools/faqs/faq.php?id=105&t=3

- https://www.eia.gov/consumption/manufacturing/

- https://ember-energy.org/latest-updates/heatwaves-doubled-electricity-demand/

- https://www.reuters.com/business/energy/us-grids-must-harness-electric-vehicle-growth-tackle-load-risks-2025-03-18/

- http://go.nature.com/3d8sd4t

- https://www.nature.com/articles/d41586-025-00616-z

- https://www.energy.gov/articles/doe-releases-new-report-evaluating-increase-electricity-demand-data-centers

- www.bloomberg.com/news/articles/2024-08-01/-electrification-is-unstoppable-a-utility-ceo-on-building-a-better-grid

- https://thesustainablechoice.com/making-sense-of-energy-units/

- https://profession.americangeosciences.org/society/intersections/faq/what-are-major-sources-and-users-energy-united-states/

- https://www.statista.com/statistics/192872/total-electricity-use-in-the-us-since-2009/

- https://www.makeitelectric.org/wp-content/uploads/2025/04/grid-reliability-study-nema-deck.pdf

- https://yaleclimateconnections.org/2024/03/the-u-s-has-never-produced-more-energy-than-it-does-today/

- https://www.scientificamerican.com/article/the-ai-boom-could-use-a-shocking-amount-of-electricity/

- https://www.cell.com/joule/fulltext/S2542-4351(23)00365-3

- https://elscotransformers.com/