ELSCO manufactures high-quality medium-voltage transformers

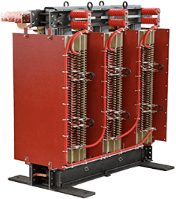

Dry Type transformers can be installed indoors or outdoors with enclosures. High voltage transformers available in standard power ratings, they are air-cooled, pollution-free and have lower fire risk.

Padmount transformers are liquid-cooled and are used when power connections are underground. Usually installed outdoors in locked enclosures on a concrete pad, they are ideal for public spaces.

ELSCO’s Selection of Transformers

Choosing the right transformer for you is not just about the specs. Low quality is the number one reason transformers fail, which costs you money, especially if it’s an unplanned failure. ELSCO Transformers manufactures high-quality medium-voltage dry type transformers. We also stock padmount transformers with ratings from 500 KVA to 2,500 KVA, with 4160, 12470, 13200 and 13800 volt primary voltages. In addition to our selection of new transformer, we maintain an updated inventory of both pre-owned copper-wound dry type and oil filled medium-voltage transformers.

Request a quote for a transformer today to optimize your business’s performance and efficiency, or call us at 800-232-9002 today to speak with a team member.