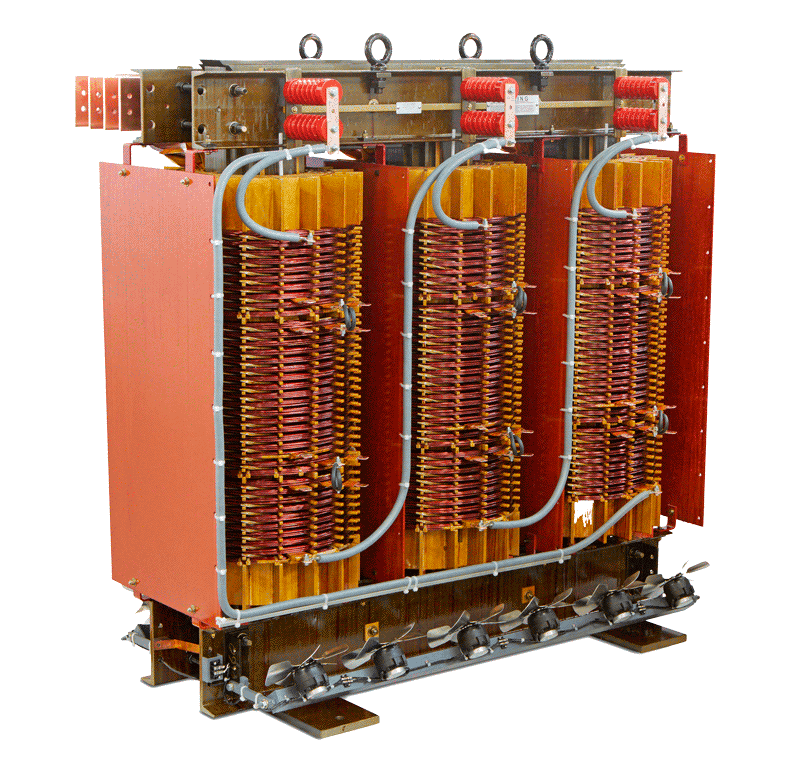

For over a century, Siemens has manufactured transformers that power commercial and industrial operations worldwide. Known for their GEAFOL cast-resin technology and fluid-filled designs, Siemens units have earned a reputation for reliability and performance. However, as these systems reach 20-plus years of service, their efficiency decreases while maintenance requirements increase.

Facility managers and business owners often turn to ELSCO Transformers for replacement solutions that restore performance without the difficulties and added costs of standard, off-the-shelf units.

Why You May Need to Replace Your Siemens Dry Type Transformer

Understanding when to replace your aging Siemens transformer can prevent decreases in performance and sudden breakdowns. Signs to look for include:

- Increased operating temperatures: The transformer’s enclosure feels unusually hot to the touch, and the surrounding areas feel warmer than normal.

- Visible leakage: The seals in older Siemens liquid-filled transformers may begin to fail and leak coolant.

- Decreased efficiency: When powering newer, more advanced equipment, many Siemens units manufactured before 2010 fall below current efficiency and performance standards.

- Physical damage: The presence of corrosion, rust or burn marks typically indicates damage to the unit’s internal components.

- Loud noises: Unusual vibrations, rattles and hums can signal loose components, overheating, or damage to the core.

Dealing with these issues proactively through planned replacement prevents the extended downtime and added costs that result from a sudden failure.

Why Choose an ELSCO Retrofit Unit for a Siemens Transformer Replacement?

ELSCO’s Siemens transformer retrofits provide many benefits over off-the-shelf replacements. Extensive modifications, like the need for rewiring or new enclosures, extend installation times and often increase costs beyond the transformer itself.

Our retrofitting process starts with understanding and documenting the specs of your existing Siemens unit. Our engineers record the dimensions, connections and performance specifications to create a replacement that works within your current setup. This approach means you can install your unit quickly and accurately, without making major changes to your facility.

Advantages of Working With ELSCO Transformers

In addition to our in-stock dry type transformers and retrofitting capabilities, we offer a complete lineup of services, from specialty bus work and custom-built units to emergency replacements and repair services for virtually any transformer brand. We focus on personalized customer service for each request, regardless of the size or scope of your project.

Other benefits you’ll enjoy when working with us include:

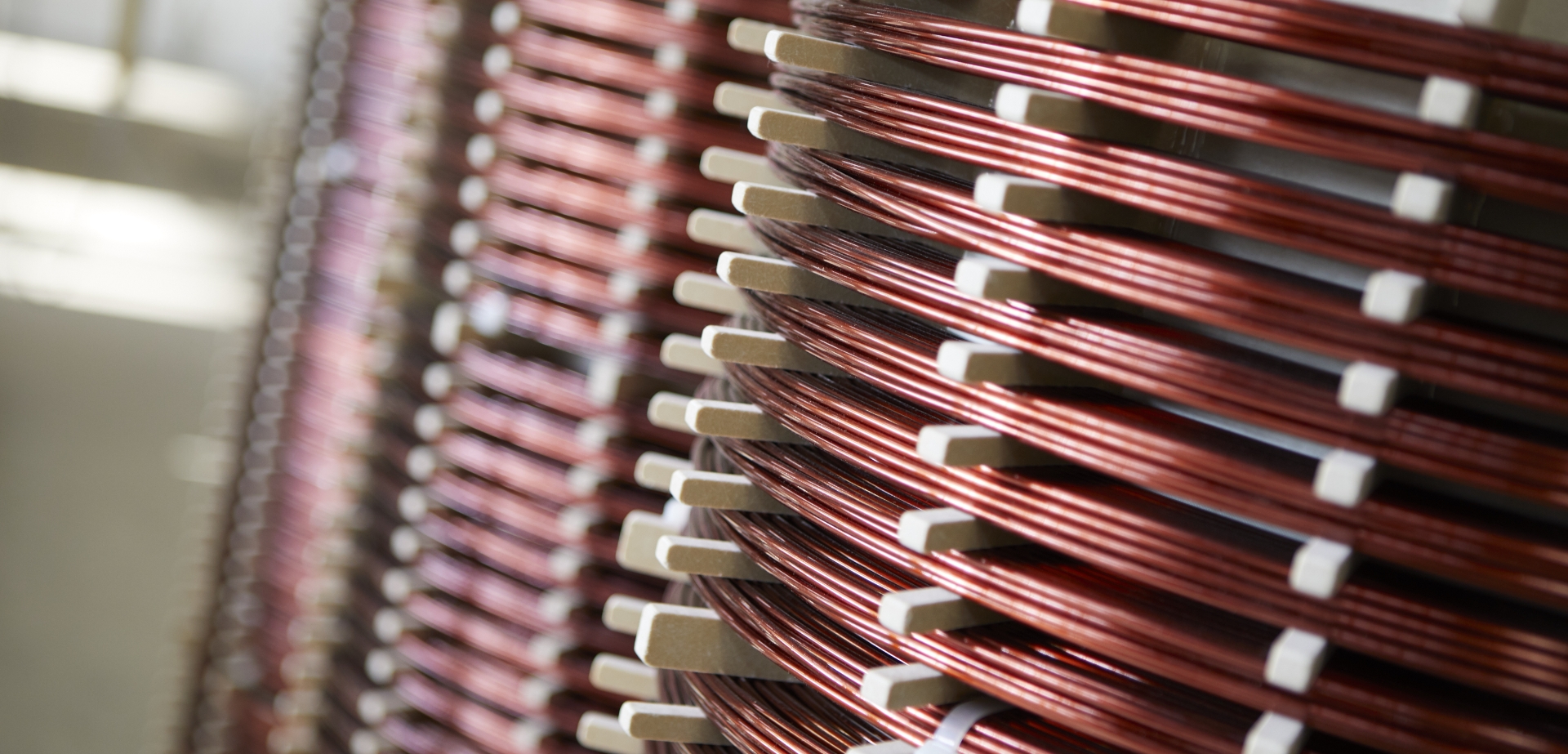

- Engineering excellence: Our engineers average over 20 years of experience with medium voltage, dry type transformer applications, bringing unmatched expertise to your replacement project.

- Fast installations: Purpose-built retrofits significantly reduce installation times over standard replacement units, minimizing downtime and saving money.

- Comprehensive warranties: We offer some of the industry’s most extensive warranties for manufacturing and materials defects in our dry type units, giving you added peace of mind.

- American manufacturing: Our Cincinnati facility has a skilled team and uses advanced techniques that deliver exceptional quality in every transformer we produce.

Learn More About Our Transformer Solutions Today

With decades of experience replacing Siemens transformers, ELSCO delivers solutions that benefit your business or organization over the long haul. Our experts are excited to learn about your application and recommend a retrofit or in-stock unit that meets your needs. Contact us online or call 800-232-9002 today for a quote or more information.